【 Máy tiện CNC-46/52 】

Hành trình trục X, Z: 750×300mm

Hệ thống điều khiển: Hệ thống Đài Loan Xin Dai / Đài Loan Bao Yuan

Công suất động cơ trục chính: 7.5KW-5000 vòng

Hệ thống trục chính: A2-5 Đài Loan Jian Chun

Đường ray vít me / bạc đạn Đài Loan Shang Yin/Yin Tai

【 CNC-46/52 Tool Changing Machine 】

X, Z Axis Travel: 750 x 300 mm

Control System: Taiwan New Era / Taiwan Baoyuan

System Spindle Motor Power: 7.5 KW - 5000 RPM

Spindle System: Taiwan Jianchun A2-5

Taiwan Hiwin / Yintai Ball Screw Guide Rails

The CNC lathe is a type of numerical control machine tool that has the following functions:

✅Efficient Turning: It can quickly and accurately complete multi-process machining of parts such as shafts and discs by installing different types of tools, allowing for multiple processes to be performed in a single setup. This reduces the number of clamping times and improves machining efficiency and precision.

✅Multiple processes can be completed, such as turning outer circles, boring inner holes, threading, and cutting. High-Precision Machining: It employs precision guide rails, lead screws, and control systems to ensure the dimensional and shape accuracy of parts.

✅Small Parts Machining: It is particularly suitable for machining small, complex-shaped parts, meeting the requirements for high precision and surface quality.

✅Automated Machining: It can be integrated with automated feeding devices for continuous automated processing, enhancing production efficiency and reducing manual labor intensity.

✅Tool Management: Tools are arranged logically for quick replacement and adjustment, improving machining flexibility.

✅Good Stability: With a compact structure and stable operation, it can maintain good accuracy and performance during long machining processes.

.jpg)

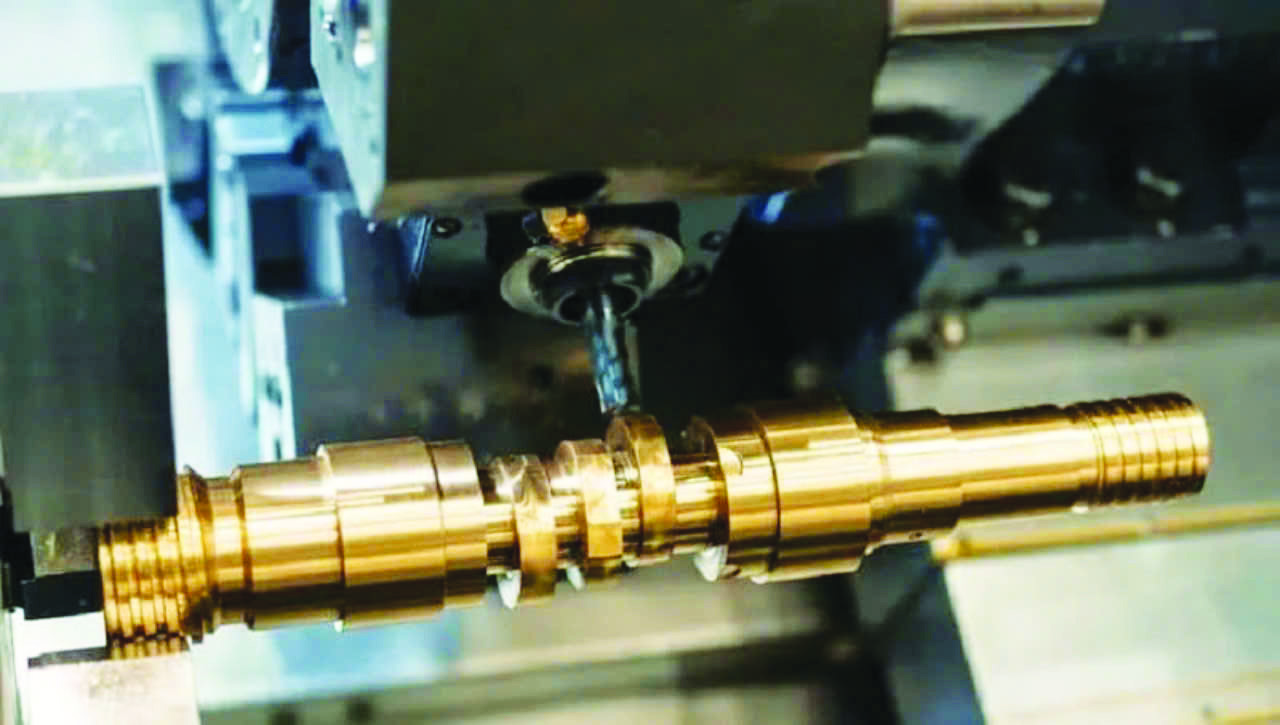

Những sản phẩm được gia công bằng máy tiện CNC

Samples of precision parts machined by CNC lathes