【 CNC-T6/T7 máy khoan phay 】

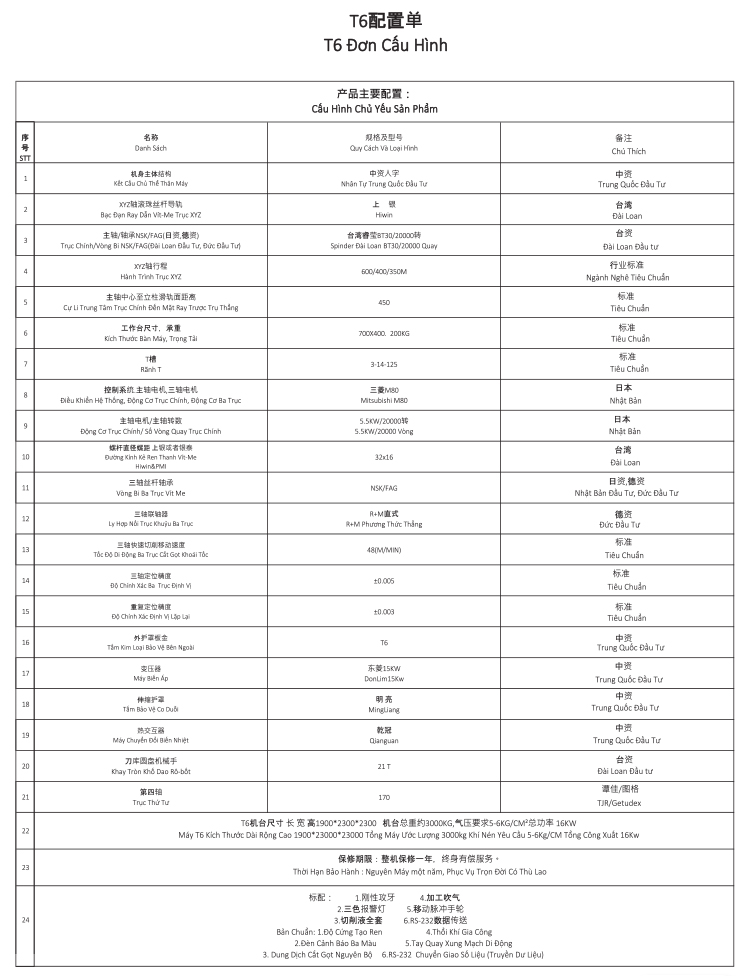

Hành trình trục X, Z, Y: 600x400×350mm

Hệ thống điều khiển: Hệ thống Mitsubishi Nhật Bản

Công suất động cơ trục chính: 5.5KW

Hệ thống trục chính: BT30-20000 vòng/phút

Bộ phận chứa dao: Servo đĩa 21T

Kích thước bàn làm việc: 700x400

Ray dẫn và trục vít Đài Loan Yinhao/Vintai

【 CNC-T6/T7 Tapping Machine 】

X, Z, Y Axis Stroke: 600×400×350mm

Control System: Mitsubishi (Japan)

Spindle Motor Power: 5.5KW

Spindle System: BT30 - 20000 RPM

Tool Magazine: Disc-type Servo 21T

Table Size: 700×400

Taiwan Hiwin/YNT Ball Screw Linear Guide

The tapping machine is a specialized machine tool designed for drilling and tapping operations, featuring the following capabilities:

1. High-speed Drilling: Equipped with a high-speed spindle, it can achieve fast and efficient drilling operations suitable for various materials, including metals and non-metals.

2. Precision Tapping: Capable of performing tapping operations with precision, ensuring the quality and accuracy of threads.

3. Multi-axis Coordination: Typically features multi-axis coordination, allowing for drilling and tapping at multiple angles and positions on complex workpieces.

4. Automated Processing: Can be integrated with automated feeding systems, robotic arms, etc., to enable automated production, enhancing production efficiency and consistency.

5. High-precision Processing: Ensures processing accuracy and repeatability through precise ball screws, linear guides, and control systems.

6. Complex Shape Processing: Capable of drilling and tapping operations on workpieces with complex profiles.

7. The tapping machine offers advantages such as high efficiency, high precision, and a high degree of automation in drilling and tapping operations, making it widely used in manufacturing industries like molds, 3C products, and automotive parts.